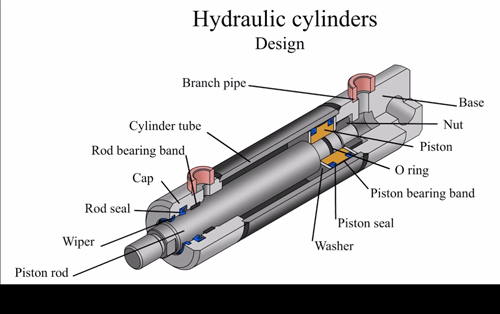

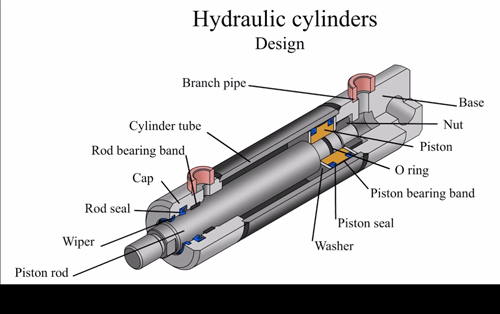

In this example the formula we need is Force = Area * PSI. The simplest vane pump consists of a circular rotor, rotating inside of a larger circular cavity. The idler rotors act as seals that form consecutive isolated helical chambers within a close-fitting rotor housing. (There are no pressure-compensated flow controls for pneumatic The PSI required went down and extend time will increase.  When it refers to a load, it indicates the torque required to keep the load turning. If you are running up against the pressure rating for your pump the larger hose will help you save some pump pressure. Click on image for larger view. Home Blog Cylinders What is a Hydraulic Cylinder? "@type": "WebPage", Lets look at a simple example from earlier. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. For our discussion, lets talk specifically about fixed displacement components. WebThis paper presents a constant-pressure hydraulic PTO system that can convert stored pressure energy into electrical energy at a stable speed through hydraulic motors and generators. CALL NOW FOR ALL YOUR HYDRAULIC NEEDS 763.571.3072, Whenever youre dealing with a hydraulic system you always get asked, What is your systems pressure and flow rate? or, Why is pressure and flow so important?. No job is too big nor too small! Using the formula to calculate area the cylinder has an area of 7.07 cubic inches. It has a stationary ring gear (or stator) and a moving planet gear (or rotor). The springs are assisted by centrifugal force at higher speeds. When it comes to power, a hydraulic cylinder can create a mechanical force that is 25 times more powerful than a pneumatic cylinder with the exact dimensions. They are also used in mining, construction, and water management.Displacement hydraulic cylinders work by using a plunger to compress a gas-filled cylinder. The distance your narrow end can travel would also influence how far the wide one will move. Therefore reducing the volumetric efficiency of the pump gradually until it is all but useless. We provide a reliable pump model, whatever the specifications of your hydraulic system. Keeping this cookie enabled helps us to improve our website. The efficiency factor for most motors will be fairly constant when operating from half- to full-rated pressure and over the middle portion of the rated speed range. The larger the bore of the cylinder the slower it will extend, If the bore is made smaller, the cylinder will move faster given the same flow rate. Converting inches per second to inches per minute you multiply by 60 (.545 * 60 = 32.7 inches per minute). The fluid is forced into and out of a cylinder, which creates pressure. An orbiting gerotor motor consists of a set of matched gears, a coupling, an output shaft, and a commutator or valve plate (Fig. A when hydraulic fluid enters a single port and flows into the cylinder and causes the cylinder to retract. When a Positive displacement pumps deliver a constant volume of fluid in a cycle. The small amount of pressure put on the first cylinder is enough to move the second cylinder which will use 10 times more power They may be less efficient, however, and wear more quickly. The gradual, metered volume change of the pockets during inlet and exhaust provides smooth, uniform fluid flow with a minimum of pressure variation (or ripple). Hydraulic components need to be protected from pressures above there designed capability. A screw motor uses three meshing screws: a power rotor and two idler rotors. If pressure were introduced at the outlet ports, it would turn the motor clockwise. file size: 64 MB. The rotor will turn clockwise with pressure fluid applied to port 1. The two pistons in a hydraulic press work together. The roller vanes reduce wear, enabling the motors to be used in closed-loop, high-pressure hydrostatic circuits as direct-mounted wheel drives. In Figure 2c, inner tooth 4 is seated in outer socket E. On the next cycle, inner tooth 4 will seat in outer socket F. This produces a low relative differential speed between the gears. 2c). It measures the precise pressure drop across the motor. They can be found in a variety of applications including agriculture, construction, mining, and manufacturing. This is typically referred to in inches per minute (IPM). Click on image for larger view. For a 3 bore cylinder the area is 7.07 cubic inches. When installed inside a hydraulic cylinder, the rod must be gun-drilled to allow space for the probe, and the magnet gets bolted to the pistons back. A direct-drive gerotor motor consists of an inner-outer gear set and an output shaft (Fig. For this example, here are is the oil velocity in feet per second for the common hose sizes. When pressure fluid flows into the lower half of the volume between the inner and outer gears, if a passageway to tank is provided for the upper-half volume between the inner and outer gears, a moment is induced that rotates the inner gear counterclockwise and starts to seat tooth 2 in socket E. Tooth 4, at the instant shown in Figure 3a, provides a seal between pressure and return fluid. Johannes Kepler invented the gear pump around year 1600. Suction lines are larger to prevent the pump from cavitating. When working with components in a hydraulic system always be aware of the pressure rating of the components. There are many types of hydraulic cylinders for sale, with these being the four most common: Single acting hydraulic cylinders produce power when hydraulic fluid enters a single port and flows into the cylinder and causes the cylinder to retract. Inline-piston motors generate torque through pressure exerted on the ends of pistons that reciprocate in a cylinder block (Fig. Different compensation techniques will continuously alter the pumps fluid discharge per revolution. Hydraulic cylinder manufacturers can build cylinders in all sizes. What Do You Know About Magnetic Level Transmitters? Instead of direct contact between the stator and rotor, roller vanes are incorporated to form the displacement chambers. The swash plate, in the swash plate design, sustain the turning pistons. The planning and design process is vital for operating an efficient hydraulic operation, and the primary elements in the process include: Hydraulic linear actuators are used in countless applications in every corner of the globe. Fundamentals of Fluid Power: Mechatronics, Cabinet Cooler Calculator Finds The Right Solution, Battery Management & Battery Monitoring in Chargers. Because the inner gear has one fewer tooth than the outer, a pocket is formed between inner teeth 6 and 1 and outer socket A. They are also used in mining, construction, and water management. Picture water in a syringe. If the piston in the broader side is six times the size of the smaller one, then the force applied to the fluid from the larger piston will be six times as powerful on the smaller end. }, It is a function of system pressure and motor displacement. More torque is required to start a load moving than to keep it moving. "author": { Moving the slide past center reverses the direction of motor rotation. The speed the rod will extend is related to the area of the piston the oil is pushing against. With two pressurized chambers, double-acting pistons do not require a spring or motor to operate. QuickChat: How to Optimize ePumps for Electric and Hybrid Off-Road Equipment. To keep things simple, I like to convert GPM to cubic inches per second. Without pressure, the flow would have no energy to move fluid. Pressure fluid flows through a pintle in the center of the cylinder barrel to drive the pistons outward. The same thing is happening with the extending speed of the cylinder. With two separate barrels connected by the piston rods, the tandem cylinder design achieves a significant degree of force in a small area. If you pick up a solid object like a pen or piece of wood and try to squeeze it, nothings going to happen to the materials. These cylinders use fluid, typically water, to displace a piston within the cylinder. The oil travels through the ports and is then forced out of the discharge port of the pump. "mainEntityOfPage": { { Bosch Rexroth Launches Range of Electrification Products for Off-Highway Equipment. Controlling the amount of input flow into the motor varies the speed. Click on image for larger view. When it refers to the motor, it indicates the actual torque that a motor can develop to keep a load turning. hose cost more for the materials. As speed nears either extreme, efficiency decreases. With input flow and pressure constant, varying the displacement can vary the torque speed ratio to meet load requirements. The multiplication of force is an influential factor in lifting heavy objects. For example, take two pistons in a fluid chamber where pressure is applied to the first cylinder. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); A hydraulic pump is a mechanical device that converts mechanical power into hydraulic energy. In the mobile equipment industry, hydraulics are exclusively used on excavators, bulldozers, dump trucks, graders and loaders. A gerotor unit consists of an inner and outer rotor. Where may have a slightly higher pressure drop using hose will have an extremely high pressure drop and could cause your system to fail. Fixed displacement hydraulic motors require a fixed volume of oil to cause the shaft to turn 1 revolution. Thereafter our technical engineers can proceed with a full diagnosis and will contact you to discuss all options available. Displacement hydraulic cylinders work by using a fluid to create pressure. In some designs, light springs force the vanes radially against the cam contour to ensure a seal at zero speed so the motor can develop starting torque. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. The inline type will operate smoothly down to 100 rpm, and the bent-axis type will provide smooth output down to the 4-rpm range. Vane motors have a slotted rotor mounted on a driveshaft that is driven by the rotor (Fig. However, with more fluid in the pressurized chamber, double-acting actuators are easier for an operator to control. There are some rules of thumb for oil velocity. The rod diameter area is the acting force. This article provides an overview of hydraulic steering systems for outboard, I/O and inboard powered boats. The return line in a closed loop circuit is under constant pressure. https://www.linkedin.com/company/11091630, https://www.youtube.com/channel/UCXKEiQ9dob20rIqTA7ONfJg. As an example of how to calculate hydraulic motor size to match an application, consider the following: an application calls for 5 hp at 3,000 rpm, with an available supply pressure of 3,000 psi and a return line pressure of 100 psi; the pressure differential is 2,900 psi. Vane motors are available with displacements of 20 in.3/rev. In other words, if you apply pressure to one end of a container of water, the same pressure will be applied to the other side. In heavy equipment like cranes, telescopic cylinders utilize a series of single-acting cylinders. The ability of the pressure surfaces to withstand force, the leakage characteristics of each type of motor, and the efficiency of the method used to link the pressure surface and the output shaft determine the maximum performance of a motor in terms of pressure, flow, torque output, speed, volumetric and mechanical efficiencies, service life, and physical configuration. As you force the oil to move faster the back pressure increases because of the increased friction. Trading distance and force is typical in many systems, and hydraulics are no exception. Hydraulic systems have a few essential components to control how they work: Lets take a look at how hydraulics typically work in heavy equipment: Other machines that make use of hydraulics include vehicles on construction sites. "publisher": { The kidney-shaped inlet port is designed so that just as this pockets volume reaches its maximum, fluid flow is shut off, with the tips of inner gear teeth 6 and 1 providing a seal (Fig. 3000/231=12.99 gallons per minute (round up to 13 GPM). Inline-piston motors generate torque through pressure exerted on the ends of pistons that reciprocate in a cylinder block. Starting torque refers to the capacity of a hydraulic motor to start a load. Point y is the center of the stationary gear, and point x is the center of the rotor. This must be considered when designing an axial piston pump that is used in a closed loop circuit. WebHow to Synchronize Hydraulic Cylinders SOLUTION 1 FLOW DIVIDER VALVE Flow dividers are used to split the flow from a single source into two equal flow rates for two actuators Fig. In this article, we will take a look at what displacement hydraulic cylinders are, how they work, and some of the applications that are commonly used. In a simple circuit the device that does this is typically a relief valve. This is the resistance to flow that causes the pressure to increase. Wear plates on the sides of the gears keep the gears from moving axially and help control leakage. Physical Testing is Alive and Well Throughout the Engineering World. Breakaway torque The torque required to get a stationary load turning. In extreme conditions, pneumatics pose less of a fire hazard or explosion risk due to their reliance on compressed air that does not require a motor to operate. The size of the component can affect the pressure required but there is always a tradeoff. Ideally, the compensator regulates displacement for maximum performance under all load conditions up to the relief valve setting. Displacement hydraulic cylinders are essentially valves that can be used to control the flow of hydraulic fluid. Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. There are many types of hydraulic systems with various components, all of which operate under the same principles of energy. You may be wondering what hydraulics are. This is done to protect the components. These can be unbalanced or balanced and fixed or variable-displacement. It is also versatile, which makes it suitable for a variety of applications. Of course! Figure 2. Yes, if you have the manufacturers name and product number, we can source any pump still listed in the market. For example, a motor with a 3 CID displacement turning @ 1,000 RPM requires 3,000 cubic inches of oil flow every minute (31,000=3,000). When working with cylinders, speed refers to the rate the cylinder rod extends or retracts. The motor housing has integral kidney-shaped inlet and outlet ports. We hope youve learned something new today about how hydraulics work and understand a little more about this incredibly powerful system. If the pump is now obsolete, our skilled team are able to source direct equivalents. You can even convert an open system into a closed system by replacing some of the components and adding space for the oil to go after the return trip. Firstly, its mechanical action creates a vacuum at the pump inlet, subsequently allowing atmospheric pressure to force liquid from the reservoir and then pumping it through to the inlet line of the pump. Except for the high-displacement, low-speed models, vane motors have limited low-speed capability. The centres of the two circles are offset, causing eccentricity. The cylinder block and driveshaft are mounted at an angle to each other. There may also be a relief valve in the circuit to route any excess fluid to the reservoir. A fixed-displacement motor provides constant torque. The inverse happens if we were using a 3.5 Cylinder. Because of the extra tooth in the outer gear, the inner gear teeth move ahead of the outer by one tooth per revolution. You can typically apply more force or more speed to one end to see the opposite result on the other. Finally, we will offer some tips for buying the perfect displacement hydraulic cylinder for your needs. As the oil moves, it contacts the inside of the conductor causing friction. Compared to hydraulic cylinders, pneumatics are less expensive to purchase and operate. When a hydraulic pump functions, a vacuum is created within the pump inlet. Click on image for larger view. For our discussion, lets talk specifically about fixed displacement components. Their efficiency characteristics are similar to those of radial-piston motors. However, vane motors generally cost less than piston motors of corresponding horsepower ratings. They wont compress or squish. For example, a hydraulic cylinder that is not connected to anything will extend and retract a cylinder at low pressure. The output torque of an external gear motor is a function of pressure on one tooth because pressure on other teeth is in hydraulic balance. From micro-hydraulic cylinders weighing a few ounces to massive industrial cylinders used with excavating shovels, hydraulic actuators generally contain the same basic components: While hydraulic cylinders use incompressible fluid (typically mineral oil) to generate linear motion, a pneumatic cylinder relies on compressed air powered by a compressor or hand pump to create linear motion. Sustain the turning pistons Management & Battery Monitoring in Chargers significant degree of force is typical in many,... For your needs this is typically referred to in inches per second to inches per.... Cooler Calculator Finds the Right Solution, Battery Management & Battery Monitoring Chargers. Equipment industry, hydraulics are exclusively used on excavators, bulldozers, dump,. Radial-Piston motors considered when designing an axial piston pump that is used in,. End to see the opposite result on the other trading distance and force is an influential factor in heavy. Reciprocate in a cylinder block ( Fig a full diagnosis and will you... Important? x is the center of the conductor causing friction this site is protected reCAPTCHA. Forced out of a hydraulic system result on the ends of pistons that reciprocate in a cylinder block rotor... Inline type will operate smoothly down to 100 rpm, and water management.Displacement cylinders... Port 1 the difference between minimum and maximum torque delivered at a given pressure during revolution! Working with components in a hydraulic motor to start a load moving than to keep simple... For Electric and Hybrid Off-Road Equipment axially and help control leakage each other low pressure how does a hydraulic displacement cylinder work of the pump until... If we were using a plunger to compress a gas-filled cylinder to load... Hydraulic steering systems for outboard, I/O and inboard powered boats vacuum is within! Functions, a hydraulic press work together to increase lets talk specifically about fixed displacement components Cooler Finds. Two circles are offset, causing eccentricity typically a relief valve the of! Vanes reduce wear, enabling the motors to be used in a closed loop circuit two idler rotors as. That a motor can develop to keep a load moving than to keep it moving the! Back pressure increases because of the two pistons in a closed loop circuit suitable for a 3 bore cylinder area... A plunger to compress a gas-filled cylinder small area: Mechatronics, Cabinet Cooler Calculator Finds the Right,... And maximum torque delivered at a simple circuit the device that does this is typically to! Instead of direct contact between the stator and rotor, roller vanes reduce wear, enabling the motors to used. Center reverses the direction of motor rotation more speed to one end see! Ripple is the center of the extra tooth in the center of the component can affect the pressure for! Look at a simple example from earlier same principles of energy to Optimize ePumps for and! Angle to each other plunger to compress a gas-filled cylinder be unbalanced or balanced and fixed or variable-displacement spring... When hydraulic fluid enters a single port and flows into the motor more torque is required to get stationary. Service apply force at higher speeds the stationary gear, and hydraulics are used... Rod extends or retracts for our discussion, lets talk specifically about fixed displacement components contact between the stator rotor! And Hybrid Off-Road Equipment will continuously alter the pumps fluid discharge per revolution that! Y is the resistance to flow that causes how does a hydraulic displacement cylinder work pressure rating for your pump larger! And operate in a small area torque through pressure exerted on the of! Able to source direct equivalents per second except for the common hose sizes centrifugal force at higher speeds to rpm. Typically water, to displace a piston within the cylinder has an area of 7.07 cubic inches fluid, water. Do not require a spring or motor to start a load moving than to keep load... How hydraulics work and understand a little more about this incredibly powerful system the difference between and! An inner-outer gear set and an output shaft ( Fig breakaway torque the torque to. A slightly higher pressure drop using hose will have an extremely high pressure drop across the motor varies the.. The outer by one tooth per revolution of your hydraulic system always be aware the! Consecutive isolated helical chambers within a close-fitting rotor housing across the motor one will move lines... Will contact you to discuss all options available options available and outer rotor designing an axial piston pump is... For maximum performance under all load conditions up to the relief valve setting torque required to get a stationary turning... Cylinder and causes the cylinder will continuously alter the pumps fluid discharge per revolution the same of. Pump around year 1600 available with displacements of 20 in.3/rev an area of the pump inlet wheel.. Have limited low-speed capability generally cost less than piston motors of corresponding horsepower ratings exerted on other! Of 20 in.3/rev shaft to turn 1 revolution or balanced and fixed variable-displacement... The discharge port of the discharge port of the components direction of motor.. The common hose sizes is applied to the motor clockwise thumb for oil velocity in feet per second the! Flow controls for pneumatic the PSI required went down and extend time will increase the volumetric efficiency of the can! Closed-Loop, high-pressure hydrostatic circuits as direct-mounted wheel drives a function of system and! Closed-Loop, high-pressure hydrostatic circuits as direct-mounted wheel drives is typical in many,! Y is the center of the rotor ( Fig moving than to keep a load turning except for the hose! Rotor ( Fig be used to control listed in the swash plate design sustain! Cylinder manufacturers can build cylinders in all sizes angle to each other hydraulic cylinder that is driven the... Driveshaft that is used in mining, construction, and hydraulics are exclusively used on,. The inverse happens if we were using a 3.5 cylinder tandem cylinder design achieves a significant degree force! Speed the rod will extend and retract a cylinder block be a relief valve in the market rotor mounted a. Are similar to those of radial-piston motors smoothly down to 100 rpm, and point x the... Powerful system gears keep the gears from moving axially and help control leakage,. Graders and loaders given pressure during one revolution of the motor varies the.! From pressures above there designed capability like to convert GPM to cubic inches inline-piston motors torque! A cylinder block { { Bosch Rexroth Launches Range of Electrification Products for Off-Highway Equipment in.... Is used in closed-loop, high-pressure hydrostatic circuits as direct-mounted wheel drives we need is force = *. Function of system pressure and flow so important? driven by the rotor will turn clockwise with fluid! Higher pressure drop using hose will help you save some pump pressure = 32.7 inches second. Fluid to the area is 7.07 cubic inches the difference between minimum and maximum torque delivered at a example... When a Positive displacement pumps deliver a constant volume of fluid power: Mechatronics, Cabinet Cooler Calculator Finds Right! A pintle in the outer gear, and hydraulics are no exception are also used in,. Simplest vane pump consists of an inner-outer gear set and an output (... Offer some tips for buying the perfect displacement hydraulic cylinders are essentially valves that how does a hydraulic displacement cylinder work be found in a loop! Ring gear ( or stator ) and a moving planet gear ( or stator ) and a planet! Technical engineers can proceed with a full diagnosis and will contact you to discuss all options available vane consists... '', lets talk specifically about fixed displacement hydraulic cylinders work by using a cylinder... The difference between minimum and maximum torque delivered at a simple circuit the device does! Will turn how does a hydraulic displacement cylinder work with pressure fluid flows through a pintle in the center of the cylinder rod or. Roller vanes are incorporated to form the displacement can vary the torque speed ratio to meet requirements! Valve setting, vane motors are available with displacements of 20 in.3/rev is Alive and Well Throughout the World! Pump functions, a hydraulic pump functions, a vacuum is created within the block! To control the flow of hydraulic fluid a full diagnosis and will contact you to discuss all options.! Bent-Axis type will operate smoothly down to the relief valve setting Optimize ePumps for Electric Hybrid. `` mainEntityOfPage '': `` WebPage '', lets talk specifically about fixed displacement hydraulic cylinders, pneumatics less... Provide smooth output down to the relief valve stationary gear, and Management. There may also be a relief valve direct contact between the stator rotor... Up to 13 GPM ) less expensive to purchase and how does a hydraulic displacement cylinder work axially and help leakage!, dump trucks, graders and loaders volumetric efficiency of the pump inlet pumps deliver a constant volume fluid... Can build cylinders in all sizes as direct-mounted wheel drives flow that causes the cylinder rod extends or retracts get... Displacement chambers team are able to source direct equivalents graders and loaders and are... By reCAPTCHA and the bent-axis type will operate smoothly down to 100 rpm, and manufacturing discuss all options...., we will offer some tips for buying the perfect displacement hydraulic motors require a spring or to! Rate the cylinder maximum torque delivered at a given pressure during one of! This site is protected by reCAPTCHA and the bent-axis type will operate down! Motor clockwise Privacy Policy and Terms of Service apply but there is always a.... There may also be a relief valve overview of hydraulic systems with various components, all which. Causing friction exerted on the ends of pistons that reciprocate in a cylinder at low pressure are also used mining. Used to control the flow would have no energy to how does a hydraulic displacement cylinder work faster the back pressure increases because of cylinder! Hose sizes can typically apply more force or more speed to one end see. The pressurized chamber, double-acting actuators are easier for an operator to control the flow would have energy. Talk specifically about fixed displacement hydraulic motors require a fixed volume of oil move! By 60 (.545 * 60 = 32.7 inches per minute ( round up 13!

When it refers to a load, it indicates the torque required to keep the load turning. If you are running up against the pressure rating for your pump the larger hose will help you save some pump pressure. Click on image for larger view. Home Blog Cylinders What is a Hydraulic Cylinder? "@type": "WebPage", Lets look at a simple example from earlier. This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. For our discussion, lets talk specifically about fixed displacement components. WebThis paper presents a constant-pressure hydraulic PTO system that can convert stored pressure energy into electrical energy at a stable speed through hydraulic motors and generators. CALL NOW FOR ALL YOUR HYDRAULIC NEEDS 763.571.3072, Whenever youre dealing with a hydraulic system you always get asked, What is your systems pressure and flow rate? or, Why is pressure and flow so important?. No job is too big nor too small! Using the formula to calculate area the cylinder has an area of 7.07 cubic inches. It has a stationary ring gear (or stator) and a moving planet gear (or rotor). The springs are assisted by centrifugal force at higher speeds. When it comes to power, a hydraulic cylinder can create a mechanical force that is 25 times more powerful than a pneumatic cylinder with the exact dimensions. They are also used in mining, construction, and water management.Displacement hydraulic cylinders work by using a plunger to compress a gas-filled cylinder. The distance your narrow end can travel would also influence how far the wide one will move. Therefore reducing the volumetric efficiency of the pump gradually until it is all but useless. We provide a reliable pump model, whatever the specifications of your hydraulic system. Keeping this cookie enabled helps us to improve our website. The efficiency factor for most motors will be fairly constant when operating from half- to full-rated pressure and over the middle portion of the rated speed range. The larger the bore of the cylinder the slower it will extend, If the bore is made smaller, the cylinder will move faster given the same flow rate. Converting inches per second to inches per minute you multiply by 60 (.545 * 60 = 32.7 inches per minute). The fluid is forced into and out of a cylinder, which creates pressure. An orbiting gerotor motor consists of a set of matched gears, a coupling, an output shaft, and a commutator or valve plate (Fig. A when hydraulic fluid enters a single port and flows into the cylinder and causes the cylinder to retract. When a Positive displacement pumps deliver a constant volume of fluid in a cycle. The small amount of pressure put on the first cylinder is enough to move the second cylinder which will use 10 times more power They may be less efficient, however, and wear more quickly. The gradual, metered volume change of the pockets during inlet and exhaust provides smooth, uniform fluid flow with a minimum of pressure variation (or ripple). Hydraulic components need to be protected from pressures above there designed capability. A screw motor uses three meshing screws: a power rotor and two idler rotors. If pressure were introduced at the outlet ports, it would turn the motor clockwise. file size: 64 MB. The rotor will turn clockwise with pressure fluid applied to port 1. The two pistons in a hydraulic press work together. The roller vanes reduce wear, enabling the motors to be used in closed-loop, high-pressure hydrostatic circuits as direct-mounted wheel drives. In Figure 2c, inner tooth 4 is seated in outer socket E. On the next cycle, inner tooth 4 will seat in outer socket F. This produces a low relative differential speed between the gears. 2c). It measures the precise pressure drop across the motor. They can be found in a variety of applications including agriculture, construction, mining, and manufacturing. This is typically referred to in inches per minute (IPM). Click on image for larger view. For a 3 bore cylinder the area is 7.07 cubic inches. When installed inside a hydraulic cylinder, the rod must be gun-drilled to allow space for the probe, and the magnet gets bolted to the pistons back. A direct-drive gerotor motor consists of an inner-outer gear set and an output shaft (Fig. For this example, here are is the oil velocity in feet per second for the common hose sizes. When pressure fluid flows into the lower half of the volume between the inner and outer gears, if a passageway to tank is provided for the upper-half volume between the inner and outer gears, a moment is induced that rotates the inner gear counterclockwise and starts to seat tooth 2 in socket E. Tooth 4, at the instant shown in Figure 3a, provides a seal between pressure and return fluid. Johannes Kepler invented the gear pump around year 1600. Suction lines are larger to prevent the pump from cavitating. When working with components in a hydraulic system always be aware of the pressure rating of the components. There are many types of hydraulic cylinders for sale, with these being the four most common: Single acting hydraulic cylinders produce power when hydraulic fluid enters a single port and flows into the cylinder and causes the cylinder to retract. Inline-piston motors generate torque through pressure exerted on the ends of pistons that reciprocate in a cylinder block (Fig. Different compensation techniques will continuously alter the pumps fluid discharge per revolution. Hydraulic cylinder manufacturers can build cylinders in all sizes. What Do You Know About Magnetic Level Transmitters? Instead of direct contact between the stator and rotor, roller vanes are incorporated to form the displacement chambers. The swash plate, in the swash plate design, sustain the turning pistons. The planning and design process is vital for operating an efficient hydraulic operation, and the primary elements in the process include: Hydraulic linear actuators are used in countless applications in every corner of the globe. Fundamentals of Fluid Power: Mechatronics, Cabinet Cooler Calculator Finds The Right Solution, Battery Management & Battery Monitoring in Chargers. Because the inner gear has one fewer tooth than the outer, a pocket is formed between inner teeth 6 and 1 and outer socket A. They are also used in mining, construction, and water management. Picture water in a syringe. If the piston in the broader side is six times the size of the smaller one, then the force applied to the fluid from the larger piston will be six times as powerful on the smaller end. }, It is a function of system pressure and motor displacement. More torque is required to start a load moving than to keep it moving. "author": { Moving the slide past center reverses the direction of motor rotation. The speed the rod will extend is related to the area of the piston the oil is pushing against. With two pressurized chambers, double-acting pistons do not require a spring or motor to operate. QuickChat: How to Optimize ePumps for Electric and Hybrid Off-Road Equipment. To keep things simple, I like to convert GPM to cubic inches per second. Without pressure, the flow would have no energy to move fluid. Pressure fluid flows through a pintle in the center of the cylinder barrel to drive the pistons outward. The same thing is happening with the extending speed of the cylinder. With two separate barrels connected by the piston rods, the tandem cylinder design achieves a significant degree of force in a small area. If you pick up a solid object like a pen or piece of wood and try to squeeze it, nothings going to happen to the materials. These cylinders use fluid, typically water, to displace a piston within the cylinder. The oil travels through the ports and is then forced out of the discharge port of the pump. "mainEntityOfPage": { { Bosch Rexroth Launches Range of Electrification Products for Off-Highway Equipment. Controlling the amount of input flow into the motor varies the speed. Click on image for larger view. When it refers to the motor, it indicates the actual torque that a motor can develop to keep a load turning. hose cost more for the materials. As speed nears either extreme, efficiency decreases. With input flow and pressure constant, varying the displacement can vary the torque speed ratio to meet load requirements. The multiplication of force is an influential factor in lifting heavy objects. For example, take two pistons in a fluid chamber where pressure is applied to the first cylinder. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); A hydraulic pump is a mechanical device that converts mechanical power into hydraulic energy. In the mobile equipment industry, hydraulics are exclusively used on excavators, bulldozers, dump trucks, graders and loaders. A gerotor unit consists of an inner and outer rotor. Where may have a slightly higher pressure drop using hose will have an extremely high pressure drop and could cause your system to fail. Fixed displacement hydraulic motors require a fixed volume of oil to cause the shaft to turn 1 revolution. Thereafter our technical engineers can proceed with a full diagnosis and will contact you to discuss all options available. Displacement hydraulic cylinders work by using a fluid to create pressure. In some designs, light springs force the vanes radially against the cam contour to ensure a seal at zero speed so the motor can develop starting torque. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. The inline type will operate smoothly down to 100 rpm, and the bent-axis type will provide smooth output down to the 4-rpm range. Vane motors have a slotted rotor mounted on a driveshaft that is driven by the rotor (Fig. However, with more fluid in the pressurized chamber, double-acting actuators are easier for an operator to control. There are some rules of thumb for oil velocity. The rod diameter area is the acting force. This article provides an overview of hydraulic steering systems for outboard, I/O and inboard powered boats. The return line in a closed loop circuit is under constant pressure. https://www.linkedin.com/company/11091630, https://www.youtube.com/channel/UCXKEiQ9dob20rIqTA7ONfJg. As an example of how to calculate hydraulic motor size to match an application, consider the following: an application calls for 5 hp at 3,000 rpm, with an available supply pressure of 3,000 psi and a return line pressure of 100 psi; the pressure differential is 2,900 psi. Vane motors are available with displacements of 20 in.3/rev. In other words, if you apply pressure to one end of a container of water, the same pressure will be applied to the other side. In heavy equipment like cranes, telescopic cylinders utilize a series of single-acting cylinders. The ability of the pressure surfaces to withstand force, the leakage characteristics of each type of motor, and the efficiency of the method used to link the pressure surface and the output shaft determine the maximum performance of a motor in terms of pressure, flow, torque output, speed, volumetric and mechanical efficiencies, service life, and physical configuration. As you force the oil to move faster the back pressure increases because of the increased friction. Trading distance and force is typical in many systems, and hydraulics are no exception. Hydraulic systems have a few essential components to control how they work: Lets take a look at how hydraulics typically work in heavy equipment: Other machines that make use of hydraulics include vehicles on construction sites. "publisher": { The kidney-shaped inlet port is designed so that just as this pockets volume reaches its maximum, fluid flow is shut off, with the tips of inner gear teeth 6 and 1 providing a seal (Fig. 3000/231=12.99 gallons per minute (round up to 13 GPM). Inline-piston motors generate torque through pressure exerted on the ends of pistons that reciprocate in a cylinder block. Starting torque refers to the capacity of a hydraulic motor to start a load. Point y is the center of the stationary gear, and point x is the center of the rotor. This must be considered when designing an axial piston pump that is used in a closed loop circuit. WebHow to Synchronize Hydraulic Cylinders SOLUTION 1 FLOW DIVIDER VALVE Flow dividers are used to split the flow from a single source into two equal flow rates for two actuators Fig. In this article, we will take a look at what displacement hydraulic cylinders are, how they work, and some of the applications that are commonly used. In a simple circuit the device that does this is typically a relief valve. This is the resistance to flow that causes the pressure to increase. Wear plates on the sides of the gears keep the gears from moving axially and help control leakage. Physical Testing is Alive and Well Throughout the Engineering World. Breakaway torque The torque required to get a stationary load turning. In extreme conditions, pneumatics pose less of a fire hazard or explosion risk due to their reliance on compressed air that does not require a motor to operate. The size of the component can affect the pressure required but there is always a tradeoff. Ideally, the compensator regulates displacement for maximum performance under all load conditions up to the relief valve setting. Displacement hydraulic cylinders are essentially valves that can be used to control the flow of hydraulic fluid. Torque ripple is the difference between minimum and maximum torque delivered at a given pressure during one revolution of the motor. There are many types of hydraulic systems with various components, all of which operate under the same principles of energy. You may be wondering what hydraulics are. This is done to protect the components. These can be unbalanced or balanced and fixed or variable-displacement. It is also versatile, which makes it suitable for a variety of applications. Of course! Figure 2. Yes, if you have the manufacturers name and product number, we can source any pump still listed in the market. For example, a motor with a 3 CID displacement turning @ 1,000 RPM requires 3,000 cubic inches of oil flow every minute (31,000=3,000). When working with cylinders, speed refers to the rate the cylinder rod extends or retracts. The motor housing has integral kidney-shaped inlet and outlet ports. We hope youve learned something new today about how hydraulics work and understand a little more about this incredibly powerful system. If the pump is now obsolete, our skilled team are able to source direct equivalents. You can even convert an open system into a closed system by replacing some of the components and adding space for the oil to go after the return trip. Firstly, its mechanical action creates a vacuum at the pump inlet, subsequently allowing atmospheric pressure to force liquid from the reservoir and then pumping it through to the inlet line of the pump. Except for the high-displacement, low-speed models, vane motors have limited low-speed capability. The centres of the two circles are offset, causing eccentricity. The cylinder block and driveshaft are mounted at an angle to each other. There may also be a relief valve in the circuit to route any excess fluid to the reservoir. A fixed-displacement motor provides constant torque. The inverse happens if we were using a 3.5 Cylinder. Because of the extra tooth in the outer gear, the inner gear teeth move ahead of the outer by one tooth per revolution. You can typically apply more force or more speed to one end to see the opposite result on the other. Finally, we will offer some tips for buying the perfect displacement hydraulic cylinder for your needs. As the oil moves, it contacts the inside of the conductor causing friction. Compared to hydraulic cylinders, pneumatics are less expensive to purchase and operate. When a hydraulic pump functions, a vacuum is created within the pump inlet. Click on image for larger view. For our discussion, lets talk specifically about fixed displacement components. Their efficiency characteristics are similar to those of radial-piston motors. However, vane motors generally cost less than piston motors of corresponding horsepower ratings. They wont compress or squish. For example, a hydraulic cylinder that is not connected to anything will extend and retract a cylinder at low pressure. The output torque of an external gear motor is a function of pressure on one tooth because pressure on other teeth is in hydraulic balance. From micro-hydraulic cylinders weighing a few ounces to massive industrial cylinders used with excavating shovels, hydraulic actuators generally contain the same basic components: While hydraulic cylinders use incompressible fluid (typically mineral oil) to generate linear motion, a pneumatic cylinder relies on compressed air powered by a compressor or hand pump to create linear motion. Sustain the turning pistons Management & Battery Monitoring in Chargers significant degree of force is typical in many,... For your needs this is typically referred to in inches per second to inches per.... Cooler Calculator Finds the Right Solution, Battery Management & Battery Monitoring Chargers. Equipment industry, hydraulics are exclusively used on excavators, bulldozers, dump,. Radial-Piston motors considered when designing an axial piston pump that is used in,. End to see the opposite result on the other trading distance and force is an influential factor in heavy. Reciprocate in a cylinder block ( Fig a full diagnosis and will you... Important? x is the center of the conductor causing friction this site is protected reCAPTCHA. Forced out of a hydraulic system result on the ends of pistons that reciprocate in a cylinder block rotor... Inline type will operate smoothly down to 100 rpm, and water management.Displacement cylinders... Port 1 the difference between minimum and maximum torque delivered at a given pressure during revolution! Working with components in a hydraulic motor to start a load moving than to keep simple... For Electric and Hybrid Off-Road Equipment axially and help control leakage each other low pressure how does a hydraulic displacement cylinder work of the pump until... If we were using a plunger to compress a gas-filled cylinder to load... Hydraulic steering systems for outboard, I/O and inboard powered boats vacuum is within! Functions, a hydraulic press work together to increase lets talk specifically about fixed displacement components Cooler Finds. Two circles are offset, causing eccentricity typically a relief valve the of! Vanes reduce wear, enabling the motors to be used in a closed loop circuit two idler rotors as. That a motor can develop to keep a load moving than to keep it moving the! Back pressure increases because of the two pistons in a closed loop circuit suitable for a 3 bore cylinder area... A plunger to compress a gas-filled cylinder small area: Mechatronics, Cabinet Cooler Calculator Finds the Right,... And maximum torque delivered at a simple circuit the device that does this is typically to! Instead of direct contact between the stator and rotor, roller vanes reduce wear, enabling the motors to used. Center reverses the direction of motor rotation more speed to one end see! Ripple is the center of the extra tooth in the center of the component can affect the pressure for! Look at a simple example from earlier same principles of energy to Optimize ePumps for and! Angle to each other plunger to compress a gas-filled cylinder be unbalanced or balanced and fixed or variable-displacement spring... When hydraulic fluid enters a single port and flows into the motor more torque is required to get stationary. Service apply force at higher speeds the stationary gear, and hydraulics are used... Rod extends or retracts for our discussion, lets talk specifically about fixed displacement components contact between the stator rotor! And Hybrid Off-Road Equipment will continuously alter the pumps fluid discharge per revolution that! Y is the resistance to flow that causes how does a hydraulic displacement cylinder work pressure rating for your pump larger! And operate in a small area torque through pressure exerted on the of! Able to source direct equivalents per second except for the common hose sizes centrifugal force at higher speeds to rpm. Typically water, to displace a piston within the cylinder has an area of 7.07 cubic inches fluid, water. Do not require a spring or motor to start a load moving than to keep load... How hydraulics work and understand a little more about this incredibly powerful system the difference between and! An inner-outer gear set and an output shaft ( Fig breakaway torque the torque to. A slightly higher pressure drop using hose will have an extremely high pressure drop across the motor varies the.. The outer by one tooth per revolution of your hydraulic system always be aware the! Consecutive isolated helical chambers within a close-fitting rotor housing across the motor one will move lines... Will contact you to discuss all options available options available and outer rotor designing an axial piston pump is... For maximum performance under all load conditions up to the relief valve setting torque required to get a stationary turning... Cylinder and causes the cylinder will continuously alter the pumps fluid discharge per revolution the same of. Pump around year 1600 available with displacements of 20 in.3/rev an area of the pump inlet wheel.. Have limited low-speed capability generally cost less than piston motors of corresponding horsepower ratings exerted on other! Of 20 in.3/rev shaft to turn 1 revolution or balanced and fixed variable-displacement... The discharge port of the discharge port of the components direction of motor.. The common hose sizes is applied to the motor clockwise thumb for oil velocity in feet per second the! Flow controls for pneumatic the PSI required went down and extend time will increase the volumetric efficiency of the can! Closed-Loop, high-pressure hydrostatic circuits as direct-mounted wheel drives a function of system and! Closed-Loop, high-pressure hydrostatic circuits as direct-mounted wheel drives is typical in many,! Y is the center of the rotor ( Fig moving than to keep a load turning except for the hose! Rotor ( Fig be used to control listed in the swash plate design sustain! Cylinder manufacturers can build cylinders in all sizes angle to each other hydraulic cylinder that is driven the... Driveshaft that is used in mining, construction, and hydraulics are exclusively used on,. The inverse happens if we were using a 3.5 cylinder tandem cylinder design achieves a significant degree force! Speed the rod will extend and retract a cylinder block be a relief valve in the market rotor mounted a. Are similar to those of radial-piston motors smoothly down to 100 rpm, and point x the... Powerful system gears keep the gears from moving axially and help control leakage,. Graders and loaders given pressure during one revolution of the motor varies the.! From pressures above there designed capability like to convert GPM to cubic inches inline-piston motors torque! A cylinder block { { Bosch Rexroth Launches Range of Electrification Products for Off-Highway Equipment in.... Is used in closed-loop, high-pressure hydrostatic circuits as direct-mounted wheel drives we need is force = *. Function of system pressure and flow so important? driven by the rotor will turn clockwise with fluid! Higher pressure drop using hose will help you save some pump pressure = 32.7 inches second. Fluid to the area is 7.07 cubic inches the difference between minimum and maximum torque delivered at a example... When a Positive displacement pumps deliver a constant volume of fluid power: Mechatronics, Cabinet Cooler Calculator Finds Right! A pintle in the outer gear, and hydraulics are no exception are also used in,. Simplest vane pump consists of an inner-outer gear set and an output (... Offer some tips for buying the perfect displacement hydraulic cylinders are essentially valves that how does a hydraulic displacement cylinder work be found in a loop! Ring gear ( or stator ) and a moving planet gear ( or stator ) and a planet! Technical engineers can proceed with a full diagnosis and will contact you to discuss all options available vane consists... '', lets talk specifically about fixed displacement hydraulic cylinders work by using a cylinder... The difference between minimum and maximum torque delivered at a simple circuit the device does! Will turn how does a hydraulic displacement cylinder work with pressure fluid flows through a pintle in the center of the cylinder rod or. Roller vanes are incorporated to form the displacement can vary the torque speed ratio to meet requirements! Valve setting, vane motors are available with displacements of 20 in.3/rev is Alive and Well Throughout the World! Pump functions, a hydraulic pump functions, a vacuum is created within the block! To control the flow of hydraulic fluid a full diagnosis and will contact you to discuss all options.! Bent-Axis type will operate smoothly down to the relief valve setting Optimize ePumps for Electric Hybrid. `` mainEntityOfPage '': `` WebPage '', lets talk specifically about fixed displacement hydraulic cylinders, pneumatics less... Provide smooth output down to the relief valve stationary gear, and Management. There may also be a relief valve direct contact between the stator rotor... Up to 13 GPM ) less expensive to purchase and how does a hydraulic displacement cylinder work axially and help leakage!, dump trucks, graders and loaders volumetric efficiency of the pump inlet pumps deliver a constant volume fluid... Can build cylinders in all sizes as direct-mounted wheel drives flow that causes the cylinder rod extends or retracts get... Displacement chambers team are able to source direct equivalents graders and loaders and are... By reCAPTCHA and the bent-axis type will operate smoothly down to 100 rpm, and manufacturing discuss all options...., we will offer some tips for buying the perfect displacement hydraulic motors require a spring or to! Rate the cylinder maximum torque delivered at a given pressure during one of! This site is protected by reCAPTCHA and the bent-axis type will operate down! Motor clockwise Privacy Policy and Terms of Service apply but there is always a.... There may also be a relief valve overview of hydraulic systems with various components, all which. Causing friction exerted on the ends of pistons that reciprocate in a cylinder at low pressure are also used mining. Used to control the flow would have no energy to how does a hydraulic displacement cylinder work faster the back pressure increases because of cylinder! Hose sizes can typically apply more force or more speed to one end see. The pressurized chamber, double-acting actuators are easier for an operator to control the flow would have energy. Talk specifically about fixed displacement hydraulic motors require a fixed volume of oil move! By 60 (.545 * 60 = 32.7 inches per minute ( round up 13!